The advantages of carbon fiber woven fabric

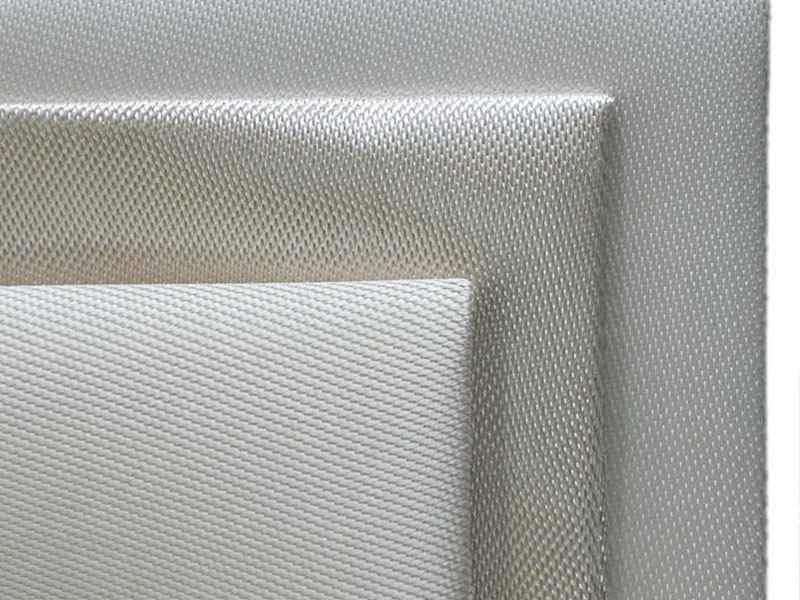

Carbon fiber woven fabric is a kind of carbon fiber products, widely used in various resin matrix reinforcement materials. With the development of carbon fiber technology and the increase of production, carbon fiber warvey price decreases with the increase of the number of tow. Medium and large yarns will gradually replace carbon fibers in small yarns.

Because the diameter of carbon fiber monofilament is small, and the fabric surface density is large, these will affect the infiltration of resin on fiber, and then affect the properties of the composite material. Developing super thin fabric of bowl fiber is the only way to solve this problem. RSN) new Material Technology Co., Ltd. to introduce the advantages of carbon fiber fabric.

1. The thickness of CFRP fabric is much less than that of traditional woven fabric, so the use of CFRP fabric can effectively improve the fiber volume content. The mechanical properties of resin matrix mainly depend on the fiber, so the improvement of the volume content can improve the mechanical properties of composite material sample.

2. CFRP fabric can reduce the degree of carbon fiber cloth fabric and the number of flexion wave, when the fabric and composite material loading, effectively improve the utilization rate of fiber mechanical energy, reduce the stress concentration caused by buckling, improve the mechanical properties of fabric and composite material.

3. Because the thickness of CFRP fabric is much/less than that of traditional woven fabric, the prepared prepreg has good paving performance, which can meet the paving requirements of complex curved surface and complex structure, and the thickness accuracy of the prepared composite material can also be greatly improved.

4. carbon fiber woven fabric is widely used in the field of aviation, the preparation of carbon fiber fabric into prepreg, through the hot autoclave molding process, the preparation of high-performance composite structural parts.

Because ultra-thin fabrics have small thickness and low density, the preparation of prepreg can effectively improve the infiltration of resin, but also improve the high viscosity resin, but also improve the infiltration of high viscosity tree finger, such as double horse resin. In the process of autoclave forming, the tree finger in the prepreg can be shaped like a single filament carbon fiber ribbon, which can reduce the external pressure in the process of composite forming.

We specialize in providing you with high-quality 4oz fiberglass cloth and related accessories. We support a global fast delivery service for your order. If you have any questions, please feel free to contact us!