Other Usage of Fiberglass Woven Roving

With the rapid development of the construction industry and the renewal of the national land policy, the common clay sintered brick has been gradually withdrawn from the market. More and more buildings require the use of light, environmental protection, good insulation performance of the wall, aerated concrete block, this light material is widely used in residential buildings, workshops, office buildings and other buildings. However, the crack problem of this kind of engineering material has not been well solved and has plagued the construction market for many years. In fact, the problem of plastering material can be solved by adding alkali resistant fiberglass woven roving on the wall of aerated concrete block.

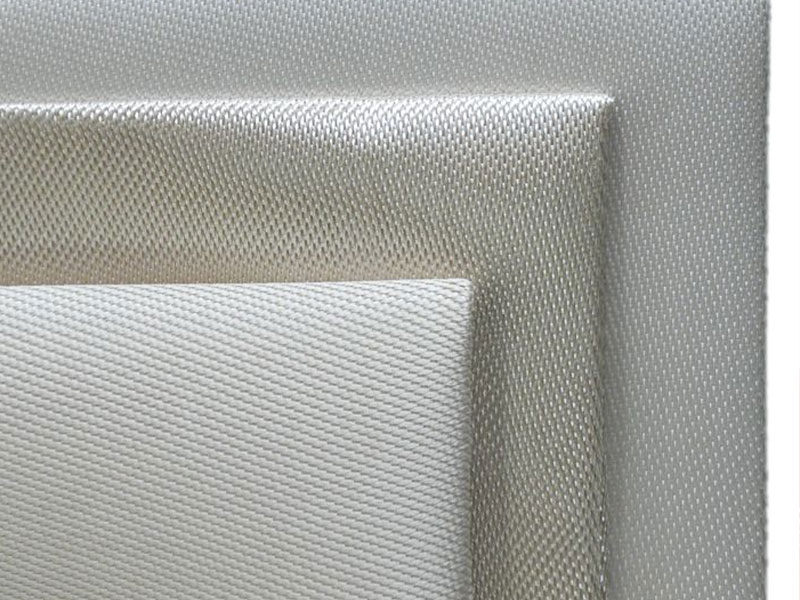

The material solves the problems of cracking, bulging and falling off caused by the shrinkage of the wall plastering layer, as well as the direct cracks between the wall and the concrete wall, column and beam. Alkali-resistantfiberglass woven roving, made of glue-added glass fiber woven into mesh, has strong tensile and alkaline resistance, and mortar has a strong adhesion, and can form a combination with mortar.

Because an alkali resistant fiberglass woven roving is set in the plastering layer, the plastering mortar and alkali resistant fiberglass mesh cloth work together to improve the tensile strength of the plastering layer, not easy to crack.Process: basic cleaning - watering and wetting - slurry - watering and maintenance - punching bars - base plastering - surface plastering - cutting and sticking alkali resistant fiberglass woven roving - hanging fine mortar - maintenance.